AI-Powered Asset Management: From Experimentation…

With the increasing air traffic, civil aviation will need a technological breakthrough to reduce emissions. Hydrogen could play a crucial role.

The propulsion technologies used in civil aviation have seen little change in recent decades. But as air traffic grows, the sector faces a complex challenge to reduce its climate impact. Some of the most promising solutions include carbon-neutral synthetic kerosene produced from hydrogen, or radically new means of propulsion, such as direct hydrogen combustion or electric motors powered by hydrogen fuel cells.

In 2018, civil aviation emitted 1.1 Gt CO2 (upstream emissions included), which is roughly 2.56% of global GHG emissions. Despite technological innovations such as motor efficiency and aircraft lightning, CO2 emissions from the aviation sector have increased by 42% between 2005 and 2019, due to the rising demand for air travel [1]. Some forecasts indicate that GHG emissions in this sector could double by 2050, assuming growth of 3-4% p.a. and an improvement in efficiency of 2% p.a. [2]. Indeed, in addition to CO2, planes emit other pollutants such as NOx or water vapor, which create contrails (a trail of ice crystals formed behind the plane) and contribute to Climate Change.

However, the Air Transport Action Group (ATAG) has committed to reducing its CO2 emissions by 50% compared to 2005 by 2050, and some airline companies such as Air France have gone further and announced that it will reduce 50% of its GHG emissions/passenger/km by 2030, compared to 2005 [3]. The International Civil Aviation Organisation (ICAO) is also aiming for carbon-neutral growth from 2020 onwards [4].

Currently, two types of low carbon technologies could reduce aviation’s climate impact and contribute to attaining these objectives:

SAFs and Power-to-Liquid have the advantage of being “drop-in fuels”, which means they do not require changes in aircraft and fuel infrastructure. In theory, these fuels can already be integrated in up to 50% of the fuel capacity of current aircrafts [6].

Among SAFs, « Power-To-Liquid » is currently the most promising option. This fuel can be considered carbon-neutral when hydrogen is produced from renewable electricity, and CO2 is captured from the air. With the expected decrease in renewable electricity prices in the near future, e-kerosene will be the most cost-efficient carbon-neutral fuel for aviation [7].

Furthermore, compared to biofuels, e-kerosene produced with Power-to-Liquid technology uses less water and no food stock, making it more sustainable than biofuel, for which production necessitates arable land and water [8]. In a context where renewable fuel demand in Europe will increase from 0.1% of jet fuel today, to 6% in 2030, these externalities are not negligible [9].

The full environmental impact of each of these fuels needs to be assessed in order for the aviation industry to reach its objectives of carbon neutrality.

When comparing sustainable aviation fuels, it is crucial to take into account other sources of emissions besides CO2. That is, even if hydrogen as a fuel does not emit CO2, emissions of other GHGs (greenhouse gases) such as NOx, water vapor, or contrails must be considered. The table below estimates the impact in CO2 equivalent of the different renewable hydrogen-based aviation fuels.

| % Reduction compared to kerosene | CO2 | NOx | Water vapor | Contrails | Reduction potential in CO2 equivalent |

|---|---|---|---|---|---|

| E-kerosene produced with hydrogen and CO2 captured from the air | -100% | -0% | -0% | -10 to -40% | -60% |

| Hydrogen turbine | -100% | -50% to -80% | +150% | -30% to -50% | -50% to -75% |

| Hydrogen fuel cell | -100% | -100% | +150% | -60% to -80% | -75% to -90% |

Hydrogen combustion occurs at a lower temperature than kerosene and therefore emits less NOx. However, the combustion of hydrogen forms heavier and thinner ice crystals (contrails) compared to those formed by kerosene combustion, therefore, their warming effect is less severe. Moreover, although hydrogen turbines and hydrogen fuel cells emit 150% more water vapor than kerosene, it does not have any material impact on their global CO2eq emissions, as water vapor has 10 times lower climate impact than CO2. [2]

New propulsion hydrogen-based fuels are more effective than e-kerosene in reducing CO2eq emissions. The difference is even more pronounced when e-kerosene is produced with CO2 capture from industries, in which case it is considered it emits only -50% CO2 than kerosene during flight.

Besides the in-flight CO2eq emissions, it is also important to assess the environmental impact of the whole production process of each fuel.

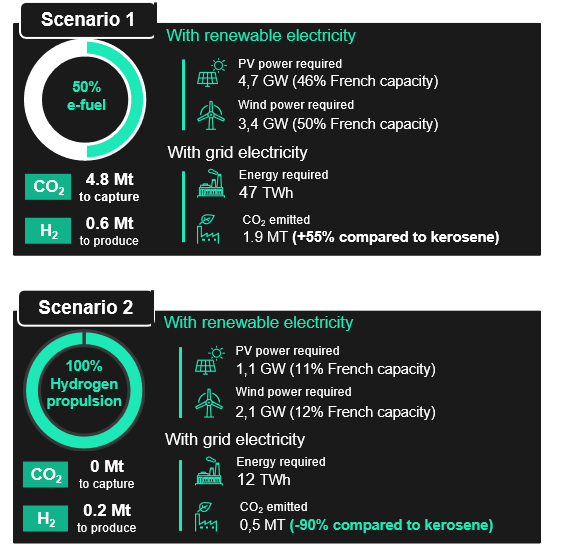

In 2019 in France, domestic flights consumed 600 million litres of kerosene and emitted 2.1 million tons of CO2. We conducted a case study to measure the impact of producing renewable hydrogen to fulfil this demand under 2 scenarios:

Direct combustion of hydrogen was chosen over fuel cell technology in this study [9] because it is more technologically advanced, as shown by the Airbus ZEROe plan. The climate impact of each scenario is calculated with two options: hydrogen is produced by electrolysis either powered by local renewable electricity or by grid electricity, based on the French electricity mix CO2eq emissions (40gCO2eq/kWh). [10]

E-kerosene is produced by the Fischer-Tropsch process, in which hydrogen and CO2 taken from industry, biomass or direct-air capture are thermally converted into syngas (a mixture of hydrogen and carbon monoxide). The syngas then undergoes a series of iron-catalyzed reactions to synthesize kerosene. As the reaction also produces a mix of fuel gases, naphtha, and other co-products, this process is quite inefficient; 1.7 tonnes of hydrogen is required to produce 1 tonne of e-kerosene. [11]

In Scenario 1, with the current electricity mix in France, the production and combustion of e-kerosene would emit 55% more CO2 than standard kerosene. Therefore, e-kerosene only reduces CO2 emissions in aviation when hydrogen is produced from renewable electricity. However, as shown in the illustration, the amounts of renewable electricity needed are substantial, as nearly 50% of the current PV and wind power generation capacity would have to be devoted to the production of e-kerosene for aviation. The alternative would be to import e-kerosene from countries with much greater renewable hydrogen production capacity, such as South America. This, however, would require creating the necessary infrastructure, such as hydrogen liquefaction assets. [12]

On the other hand, in Scenario 2, direct combustion of hydrogen requires less hydrogen input, thus less electricity and CO2eq emissions (-90% compared to kerosene with the French electricity mix). However, although hydrogen-powered aircrafts have already been developed, for example in 1980 in the USSR, they are not technically and commercially available. Airbus plans the first commercial flights of its ZEROe plane for 2035. This is due to the many technical challenges that need to be overcome.

First of all, hydrogen gas is highly flammable and creates explosive mixtures with air and oxygen, so strict regulations and safety certifications are needed before using this fuel for aviation [13]. However, the main problem with hydrogen is its volumetric energy density, which is three times lower than kerosene for liquid hydrogen stored at -253°C, and seven times lower for gaseous hydrogen [1]. Therefore, storing hydrogen requires at best three times more space than kerosene for the same flight. This means that the low energy density of hydrogen makes it less suitable for long-haul flights, compared to SAFs.

However, some research is underway to overcome this challenge, for example by placing hydrogen tanks in the fuselage of the aircraft and reducing their mass through the use of lightweight material. Hydrogen turbines are also being optimized for climate impact, to achieve very low NOx emissions while having high efficiency and thrust. [2]

Another challenge for the uptake of hydrogen propulsion is the adaptation of airport infrastructure, with storage, distribution, and even production facilities to develop, with all the safety challenges around Hydrogen. The ADP Group, which manages Paris airports, launched a call for hydrogen projects in February 2021, and selected 11 projects on the storage, transport and distribution of hydrogen, as well as the diversification of hydrogen uses in the airport and the circular economy around hydrogen.

Based on these conclusions, the mid-term emission reduction objectives of the aviation industry can only be achieved with SAFs and there is an immediate need for the aviation industry to invest in hydrogen technologies for long-term net-zero objectives. It can be expected that by 2050, a mix of these solutions will be used. This mix is likely to include hydrogen propulsion for short and medium distances and SAFs for more energy-intensive flights. But this will require significant investments in research and development, as well as regulatory changes to ensure safe and economical hydrogen flights.

Case study parameters

[1] Pouvoir voler en 2050, Shift Project, March 2021

[2] Hydrogen-Powered aviation, FCH, May 2020

[3] Air France Horizon 2030, April 2021

[5] Le procédé Fischer-Tropsch, IFP, 2009

[6] ASTM D7566 Standard, ICAO CAAF/2-WP/7

[7] True Cost of Solar Hydrogen, September 2021

[8] Sustainable aviation fuels, European Parliament, 2020

[9] Sia Partners case study, May 2021

[10] éCO2 mix – Les émissions de CO2 par kWh produit en France, RTE

[11] Production of synthetic kerosene and its market forecast, Pasi Halonen, Lappeenranta-Lahti University of Technology LUT, 2020

[12] Hydrogen in Latin America, IEA, August 2021

[13] Afhypac, Inflammabilité et explosivité de l’hydrogèn, 2020

Fiche 7.1 - Inflammabilité Rév. avril 2020_PM (afhypac.org)